Kuti tigwiritse ntchito mapulojekiti azitsulo za hardware, mainjiniya athu amasankha mosamala njira zoyendetsera zinthu zosiyanasiyana.

Njira zodziwika bwino zopangira zinthu za Hardware pakadali pano ndi:

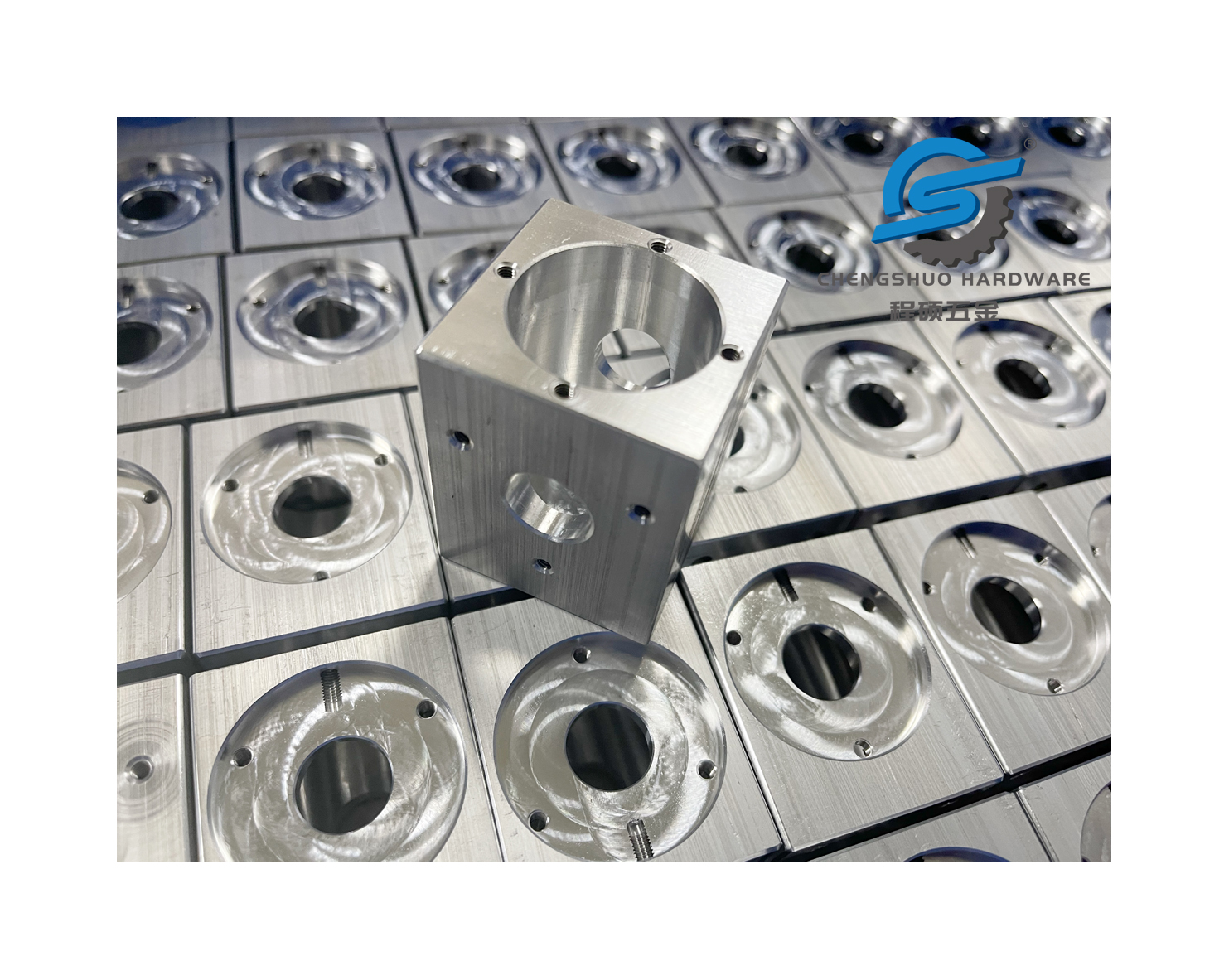

1. CNC Machining

CNC kutembenuka, mphero, kukhomerera, CNC cutting processing amatanthauza njira yodula chidutswa cha ntchito mu mawonekedwe ofunikira ndi kukula kudzera mu chida chodulira. Njira zodulira wamba zimaphatikizapo kutembenuza, mphero, kubowola, ndi zina.

Zina mwa izo, kutembenuza ndiko kugwiritsa ntchito zida zodulira pa lathe kuti zisinthe zidutswa za ntchito zozungulira, zomwe zimatha kupanga magawo osiyanasiyana amtundu, kutalika, ndi mawonekedwe;

Kugaya ndikugwiritsa ntchito zida zodulira pamakina amphero kuti azizungulira ndikusuntha zidutswa zantchito, zomwe zimatha kupanga mawonekedwe osiyanasiyana athyathyathya ndi mawonekedwe a convex concave a magawo;

Kubowola ndi kugwiritsa ntchito zida zodulira pamakina obowola pobowola mabowo mu zidutswa zogwirira ntchito, zomwe zimatha kupanga mabowo amitundu yosiyanasiyana ndi kuya.

Chengshuo yagwiritsa ntchito makina athu a CNC, omwe atha kupereka ntchito zoyimitsa kamodzi pazogulitsa zolondola kwambiri ndi zida zosiyanasiyana.

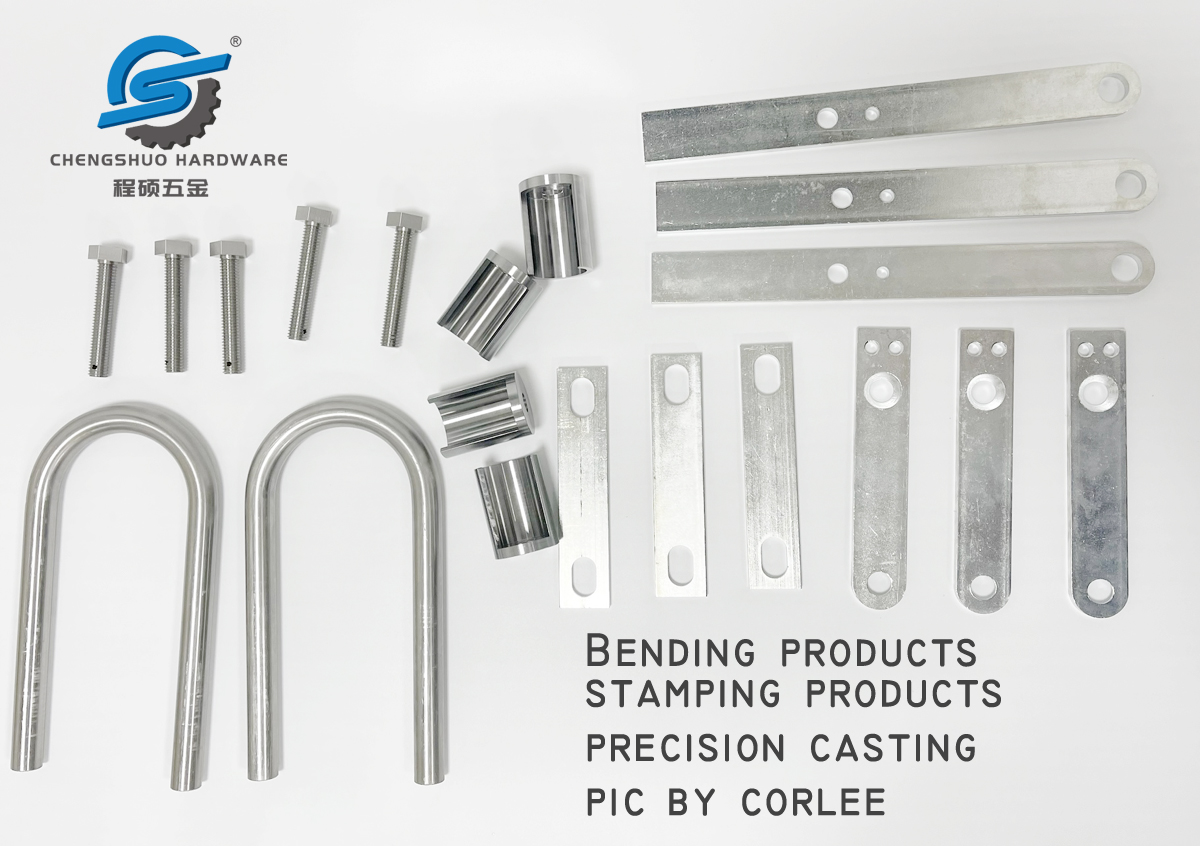

2. Stamping processing - Stamping center

Kusindikiza kumatanthawuza njira yosindikizira mapepala achitsulo mu mawonekedwe omwe mukufuna kudzera muzithunzithunzi. Common stamping njira monga kudula, kukhomerera, kupinda, etc. Pakati pawo, kudula ndi kudula zitsulo pepala molingana ndi kukula kwake kuti apeze kukula chofunika mbali lathyathyathya. Kukhomerera ndiko kugwiritsa ntchito nkhungu pamakina okhomerera nkhonya pepala lachitsulo, lomwe lingathe kupeza maonekedwe osiyanasiyana ndi kukula kwa mabowo; Kupinda ndikugwiritsa ntchito makina opindika kupindika zitsulo, zomwe zimapangitsa kuti pakhale mawonekedwe osiyanasiyana komanso makona a magawo.

Stamping die ndi zida zapadera zomwe zimagwiritsidwa ntchito popondaponda pozizira pokonza zinthu (zitsulo kapena zitsulo) kukhala magawo (kapena zinthu zomwe zatha), zomwe zimatchedwa kuzizira kupondapo kufa (komwe kumadziwika kuti kupondaponda kufa)

Magulu odziwika bwino a ma stamping molds:

(1) Chikombole chimodzi chokha ndi nkhungu yomwe imamaliza njira imodzi yokha yosindikizira pamtundu umodzi wa makina osindikizira.

(2) Chikombole chamagulu chimakhala ndi malo amodzi okha, ndipo pamtundu umodzi wa atolankhani, ndi nkhungu yomwe imamaliza njira ziwiri kapena kuposerapo nthawi imodzi pa malo omwewo.

(3) Progressive die (yomwe imadziwikanso kuti kufa kosalekeza) ili ndi malo awiri kapena kuposerapo polowera kudyetsa zopangira. Ndi nkhungu yomwe imamaliza njira ziwiri kapena zingapo zopondaponda pamagawo osiyanasiyana osindikizira.

(4) Kutengerako nkhungu kumaphatikiza mawonekedwe a zisankho zamtundu umodzi ndi zisankho zopita patsogolo. Pogwiritsa ntchito makina otengera manja a robotic, mankhwalawa amatha kusamutsidwa mwachangu mkati mwa nkhungu, kuwongolera kwambiri kupanga, kuchepetsa ndalama zopangira, kupulumutsa ndalama zakuthupi, ndikuwonetsetsa kukhazikika komanso kodalirika.

3. kuwotcherera processing

Kuwotcherera kumatanthauza njira yolumikizira zida ziwiri kapena zingapo zachitsulo kudzera mu kutentha, kusungunuka, kapena kukakamiza. Njira zowotcherera wamba zimaphatikizapo kuwotcherera kwa arc, kuwotcherera kwa fluorine arc, kuwotcherera kwa gasi, ndi zina zambiri. Pakati pawo, kuwotcherera kwa arc kumagwiritsa ntchito kutentha kwa arc komwe kumapangidwa ndi makina otsekemera kuti asungunuke ndikulumikiza zida zachitsulo pamodzi; ammonia arc kuwotcherera kumagwiritsa ntchito kutentha kopangidwa ndi ammonia arc pansi pa chitetezo cha gasi wotchinga kuti asungunuke ndikulumikiza zida zachitsulo palimodzi; kuwotcherera gasi kumagwiritsa ntchito kutentha kwa lawi lopangidwa ndi kuyaka kwa gasi kusungunula ndikulumikiza zida zachitsulo palimodzi.

4. Kupiringa processing - kupinda pakati

Kupinda kumatanthawuza njira yopindika zinthu zachitsulo kukhala mawonekedwe omwe mukufuna kudzera pamakina opindika. Njira zopindika wamba zimaphatikizapo kupindika kwa V, kupindika kwa U, kupindika kwa Z, ndi zina zambiri. Pakati pawo, kupindika kwa V kumatanthawuza kupindika pepala lachitsulo pamakona ena kuti apange mawonekedwe a V; Kupinda kokhala ngati U kumatanthauza kupindika chitsulocho pa ngodya inayake kuti apange mawonekedwe ooneka ngati U; Z-kupindika ndi njira yopindika pepala lachitsulo pamakona ena kuti apange mawonekedwe a Z

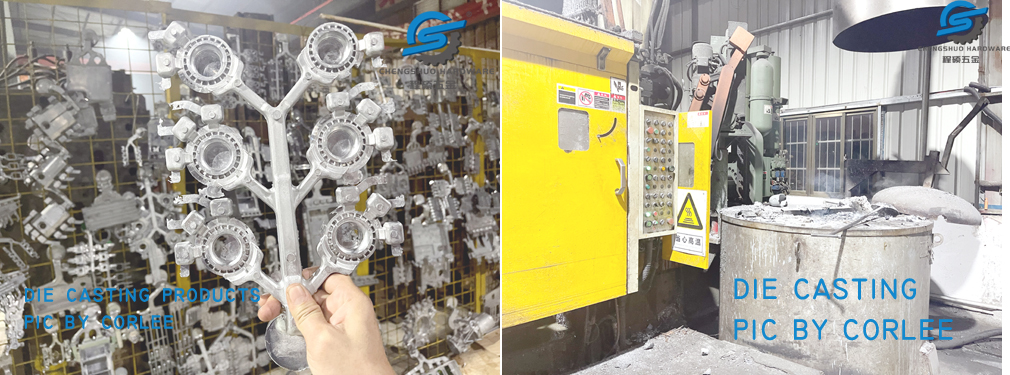

5. Die kuponyera processing - Die kuponyera likulu

Nthawi zambiri amagwiritsidwa ntchito popanga zinthu za Hardware. Die casting ndi chidule cha kuponyera kwa pressure. Ndi njira yodzaza pabowo la nkhungu yoponyera kufa ndi chitsulo chamadzimadzi kapena semi-madzimadzi pamphamvu kwambiri komanso kulimba mwachangu ndikukakamizidwa kuti mupeze kuponyera. Chikombole chakufa chomwe chimagwiritsidwa ntchito chimatchedwa nkhungu yoponyera imfa.

6. Waya kudula processing

Chengshuo Hardware ili ndi zida zake zodulira waya. Kudula mzere ndi chidule cha kudula mzere, kunena za njira yopangira. Iwo anayamba pa maziko a magetsi kumaliseche perforation ndi kupanga processing. Ndi njira yopangira yomwe imagwiritsa ntchito mawaya achitsulo (waya wa molybdenum, waya wamkuwa, kapena waya wa alloy) ngati mawaya a electrode, ndipo imapanga kutentha kwambiri kudzera pakutulutsa kwamagetsi pakati pa mawaya a elekitirodi ndi chogwirira ntchito, ndikupangitsa chitsulo kusungunuka kapena kusungunuka, kupanga. kudula seams, motero kudula mbali.

Pambuyo pokonza mosiyanasiyana, mankhwalawa amathandizidwa ndi mankhwala osiyanasiyana.

Kuchiza pamwamba kumatanthawuza njira yoyeretsera pamwamba, kuchotsa dzimbiri, anti-corrosion, kupopera mbewu mankhwalawa ndi mankhwala ena a hardware. Common padziko mankhwala monga pickling, electroplating, kupopera mbewu mankhwalawa, etc. Pakati pawo, kutsuka asidi ndi ntchito njira acidic kuti dzimbiri ndi kuyeretsa pamwamba pa hardware zigawo zikuluzikulu, kuchotsa oxides ndi dothi padziko. Electroplating ndikugwiritsa ntchito electrolysis kuyika ayoni zitsulo pamwamba pa zida za hardware kuti apange filimu yoteteza ndikuwongolera kukana kwa dzimbiri; Kupopera mbewu mankhwalawa ndi kugwiritsa ntchito zida zopopera mbewu mankhwalawa kuti azipaka utoto wofanana pamwamba pa zida za Hardware, kupanga filimu yoteteza kuti ipititse patsogolo kukongola kwawo komanso kukana nyengo.

Nthawi yotumiza: Dec-13-2023